In a landmark achievement for Nigeria and the broader West and Central African region, Afrimedical Manufacturing and Supplies Limited has made history by becoming the first syringe manufacturer in the area to be prequalified by the World Health Organisation (WHO).

The development signals a major leap forward for Nigeria’s local medical manufacturing industry and its capacity to meet global standards in healthcare delivery.

The WHO pre-qualified Afriject 0.5ml Auto-Disable (AD) Syringes—manufactured by Afrimedical—after an intensive evaluation process. This is the first time a locally-produced syringe in the region has met the WHO’s rigorous standards for quality, safety, and performance. With this certification, Afrimedical’s products are now eligible for procurement by global health bodies, including United Nations agencies and major international donors.

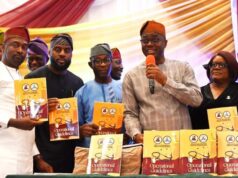

The announcement was made by the Director General of the National Agency for Food and Drug Administration and Control (NAFDAC), Prof Mojisola Adeyeye. She described the milestone as a “landmark event” in Nigeria’s public health and industrial development journey. “This is undoubtedly the outcome of meaningful collaboration between Afrimedical and NAFDAC. With this achievement, Afrimedical becomes the first syringe manufacturer in West Africa to be recognised by WHO for compliance with Good Manufacturing Practices (GMP),” Prof. Adeyeye said.

The achievement follows a rigorous prequalification process by WHO, in which NAFDAC played a pivotal role. The agency provided comprehensive technical support, facilitated regular inspections, and ensured the company’s operations were aligned with international standards. The United Nations Children’s Fund (UNICEF) also offered technical guidance to support Afrimedical through the certification process. Afrimedical’s journey to WHO prequalification can be traced back to 2019, when NAFDAC introduced the 5+5 regulatory directive aimed at reducing dependence on imports and promoting local manufacturing. The COVID-19 pandemic exposed the dangers of relying heavily on foreign medical supplies, prompting Nigerian authorities to ramp up efforts to boost domestic production capacity.

Despite Nigeria having an installed syringe production capacity of over 2.5 billion annually, many local manufacturers were operating below 20% due to competition from cheaper—sometimes substandard—imports. To address this, NAFDAC launched a quality assessment initiative that confirmed locally-manufactured syringes were comparable to foreign ones, leading to renewed support for indigenous producers. Afrimedical, one of the few fully functional syringe manufacturers in Nigeria as of 2023, took a bold step to pursue WHO prequalification. With NAFDAC’s consistent backing—ranging from technical training to GMP audits—the company upgraded its facilities and processes and obtained ISO 13485 certification, a globally recognised benchmark for quality management systems in medical devices.

Prof. Adeyeye called on other local manufacturers to follow Afrimedical’s example and deepen collaboration with NAFDAC to meet global standards. She also urged procurement agencies to prioritise certified local products in line with President Bola Ahmed Tinubu’s industrialisation and self-reliance agenda. “This achievement is not just for Afrimedical; it is for Nigeria, West Africa, and the entire continent. It proves that with the right regulatory framework, technical guidance, and government support, African manufacturers can meet and exceed global expectations.”

The General Manager of Afrimedical, Gabi Al-Aridi, thanked the Federal Government and NAFDAC for their support. He noted that the WHO certification will open new global markets for the company, enabling it to contribute to vaccine delivery efforts and other immunisation programs worldwide. This breakthrough not only sets a new benchmark for medical manufacturing in Nigeria but also offers a hopeful outlook for a continent striving for health sovereignty and industrial self-sufficiency.

Credit: thenationonlineng.net